Henan Yuandake Refractory Materials Co., Ltd.

Henan Yuandake Refractory Materials Co., Ltd.

From Chinese state-owned enterprise heritage to intelligent factories, Yuandake creates green, intelligent, and reliable high-temperature solutions with three generations of dedication

36 professional refractory material products to meet various high-temperature industrial needs

Loading product data...

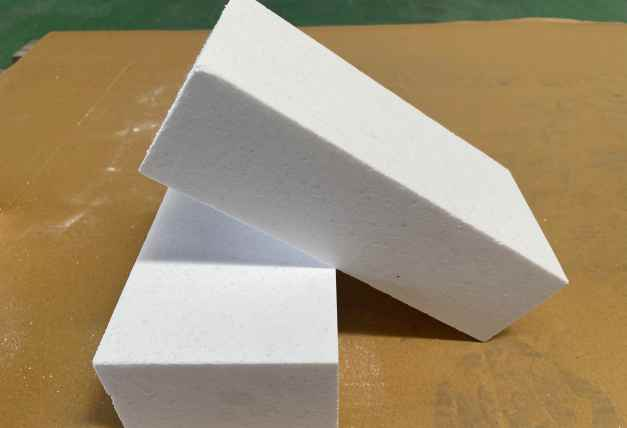

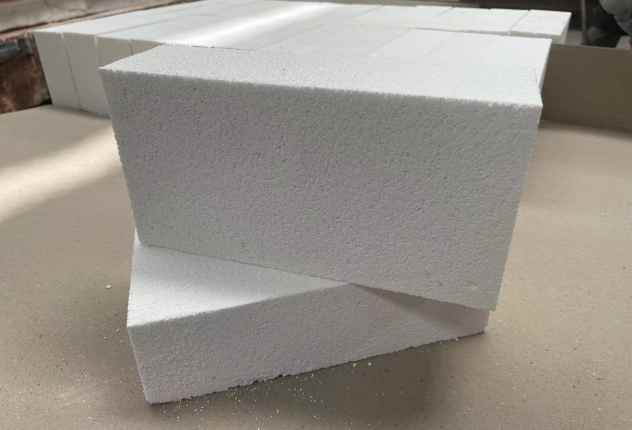

Suitable for high-temperature industrial kilns with excellent refractory performance and mechanical strength

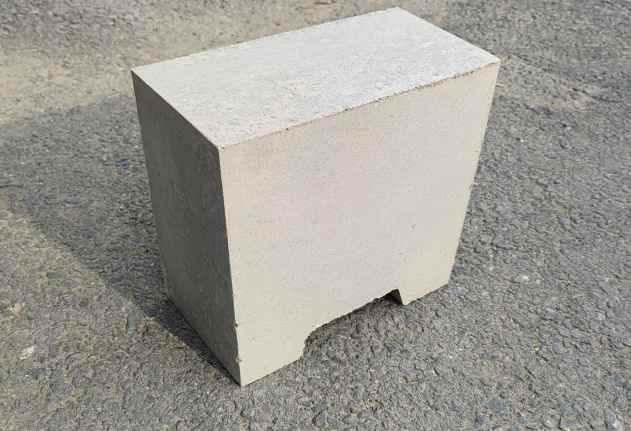

General-purpose refractory brick widely used in various industrial kiln linings

Excellent high-temperature performance, suitable for coke ovens, blast stoves and other high-temperature equipment

Excellent thermal shock resistance, suitable for environments with severe temperature changes

Lightweight insulation material with excellent thermal insulation properties

Balanced silica content for moderate high-temperature applications

Standard silica brick for general high-temperature applications

Steel fiber reinforced castable with enhanced mechanical strength and thermal shock resistance

High alumina content castable for extreme high-temperature applications

Lightweight mullite brick combining thermal insulation with structural strength

Specialized refractory brick for coke oven applications

Molybdenum-containing silica brick with special manufacturing process

Hot blast stove checker brick with special structural design

Hot blast stove specific silica brick with high purity silica material

Hot blast stove clay checker brick with specialized structural design

Various unshaped refractory materials to meet different construction needs

Blast furnace specific ceramic cup with excellent erosion resistance

High temperature chrome corundum castable with excellent slag resistance

Refractory spray material suitable for spray construction

High purity corundum balls available in various specifications

Ultra high temperature corundum brick for extreme temperature environments

Phosphate bonded wear resistant brick with excellent abrasion resistance

Phosphate bonded brick with rapid hardening characteristics

Basic refractory brick with excellent slag resistance

Ultra high temperature lightweight material with significant energy saving effect

High wear resistant ceramic material for abrasive environments

Corundum mullite composite material with excellent high temperature performance

Lightweight high alumina material with significant insulation and energy saving effects

Multi-functional combination refractory brick for special furnace structures

Mullite aggregate insulating brick with excellent thermal insulation

High alumina insulating brick with high refractoriness

Lightweight fireclay insulating brick for industrial kilns

Corundum castable with high refractoriness and corrosion resistance

Precast corundum silicon carbide refractory with superior performance

Refractory ball for regenerators with high heat storage efficiency

Export grade unshaped refractory products compliant with EU standards

Three generations of craftsmanship, ISO certified quality

Global supply chain, on-time delivery

Large-scale capacity, rapid response

International quality management system

Professional solutions tailored to your needs

Professional technical support around the clock